Best Leak-Proof Packaging container mould manufacturer : Aastha Enterprises

Best Leak-Proof Packaging container mould manufacturer : Aastha Enterprises

In the packaging industry, and when producing thousands of parts and products every day, it can be challenging to find the best possible packaging for costumes, cosmetics, pharmaceuticals, and even industrial products. The last thing any producer wants to think about is their container mould- but the right container mould can make all the difference. The selection of Container Mould Manufacturers is critical for assuring quality, consistency and production cost. So, with plenty of options on the market today, how can you know which container mould manufacturer is going to be the best for your business?

This article will walk you through the top factors to consider when selecting a container mould manufacturer and as it relates to your ultimate production and packaging performance. We'll break down how and why other concurrent industries like Sealing Wad Manufacturers, Aluminium Foil Induction Sealing Wad Manufacturers, etc. The right packaging does not start with the mould.

Let’s start with the preliminary information. A container mould is the primary element of your product packaging. Quality moulds ensure each and every container that comes off your production line is consistent, strong, and compliant with industry standards. Even a small error in a poorly manufactured mould can lead to irregular shapes, weak structural integrity, or instances where there is a production halt because things break or do not come out the same.

Top quality Container Mould Manufacturers provide something more than just another product; the peace-of-mind that comes with precise engineering, a product made with quality materials, and excellent after-sales service. If you are ready to scale your business or are launching a new product line, then investing in consistent moulds would be the number one item on your priority list.

Look at how long the manufacturer has been in business. A good Container Mould Manufacturers will have a portfolio of previous projects, testimonials, and possibly some case studies. And don't even hesitate to ask them for references or samples.

Every business has unique requirements. An effective mould manufacturer should provide customization options based on the size, shape, material, and production volume of your container.

Modern-day manufacturing involves using CNC machines, CAD/CAM software, and advanced prototyping trends. Make sure the manufacturer you choose uses modern technology to create accuracy and consistency.

Ask about their quality assurance procedures. Do they actually test the moulds under real-time production? What is their protocol for defects? Quality should never be compromised.

Cost is significant, but cheap is not always best. Don't look for the cheapest price you can get. Instead look at your overall value - durability, production volume, and life expectancy have to be taken into account.

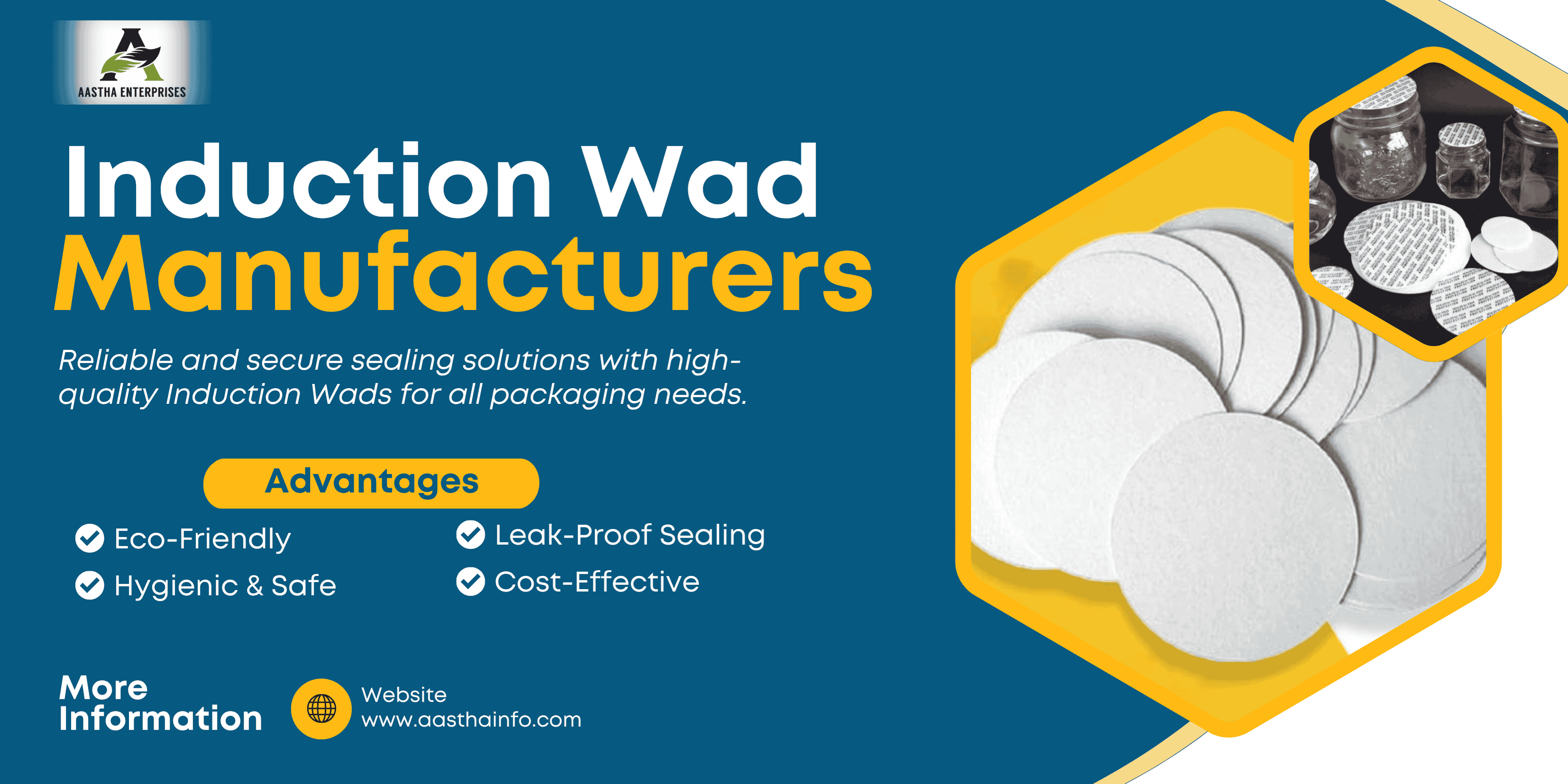

While the container is the structural body, sealing solutions such as Induction Sealing Wads are the closure and protection. When choosing a container mould without thinking about the seal, that is like buying shoes without knowing your size.

Use due diligence with Sealing Wad Manufacturers and Induction Wad Manufacturers to have lids and wads that fit the mouth of the container they will be used on. For example, if the containers are plastic or glass, you may require wads that are compatible with the Aluminium Foil Induction Sealing Wad Manufacturers. These wads create tamper-proof protection and sustain shelf life, and are specially used with food and pharmaceutical products.

A mid-sized cosmetics brand in India was struggling with leakages and irregular containers, affecting their brand image and customer trust. After switching to a reliable Container Mould Manufacturer and partnering with trusted Induction Sealing Wad Manufacturers, they saw a 40% reduction in product complaints and a 25% increase in production efficiency within three months. The improvement in packaging also boosted their retail appeal, leading to better shelf placement.

Lack of Technical Support: Stay away from manufacturers that cannot offer technical support or technical consultation.

No Quality Certifications: A lack of ISO and/or other industry certification means that they do not have standardized processes.

One-size-fits-all Approach: Your business is unique, stay away from suppliers that don’t offer customized solutions.

Poor Communication: Communication is significant during mould development, through production, and after the sale.

Choosing the right partners throughout the packaging chain is more than just a sales transaction, it's a recognized commitment to the quality of your product, and reputation of your brand. The best Container Mould Manufacturers know this and work in strong partnership with either companies, or their suppliers to deliver consistent, scalable package solutions.

Likewise, don't discount how important it is to choose smart Induction Wad Manufacturers, and sealing Wad Manufacturers. They are working together to enhance product packaging examples, product security, tamper-proofing and interest.

Wanting to enhance your packaging? Be it specific container moulds or professional sealing wads, we can help you find reliable, manufacturer suppliers in the industry.

Let’s build something reliable together.

For inquiries, detailed product information, or to discuss your specific requirements, feel free to reach out to our dedicated team.

Plot no 37, sector 10A, Vasundhara, Ghaziabad, Uttar Pradesh, India -201012

Plot no 37, sector 10A, Vasundhara, Ghaziabad, Uttar Pradesh, India -201012