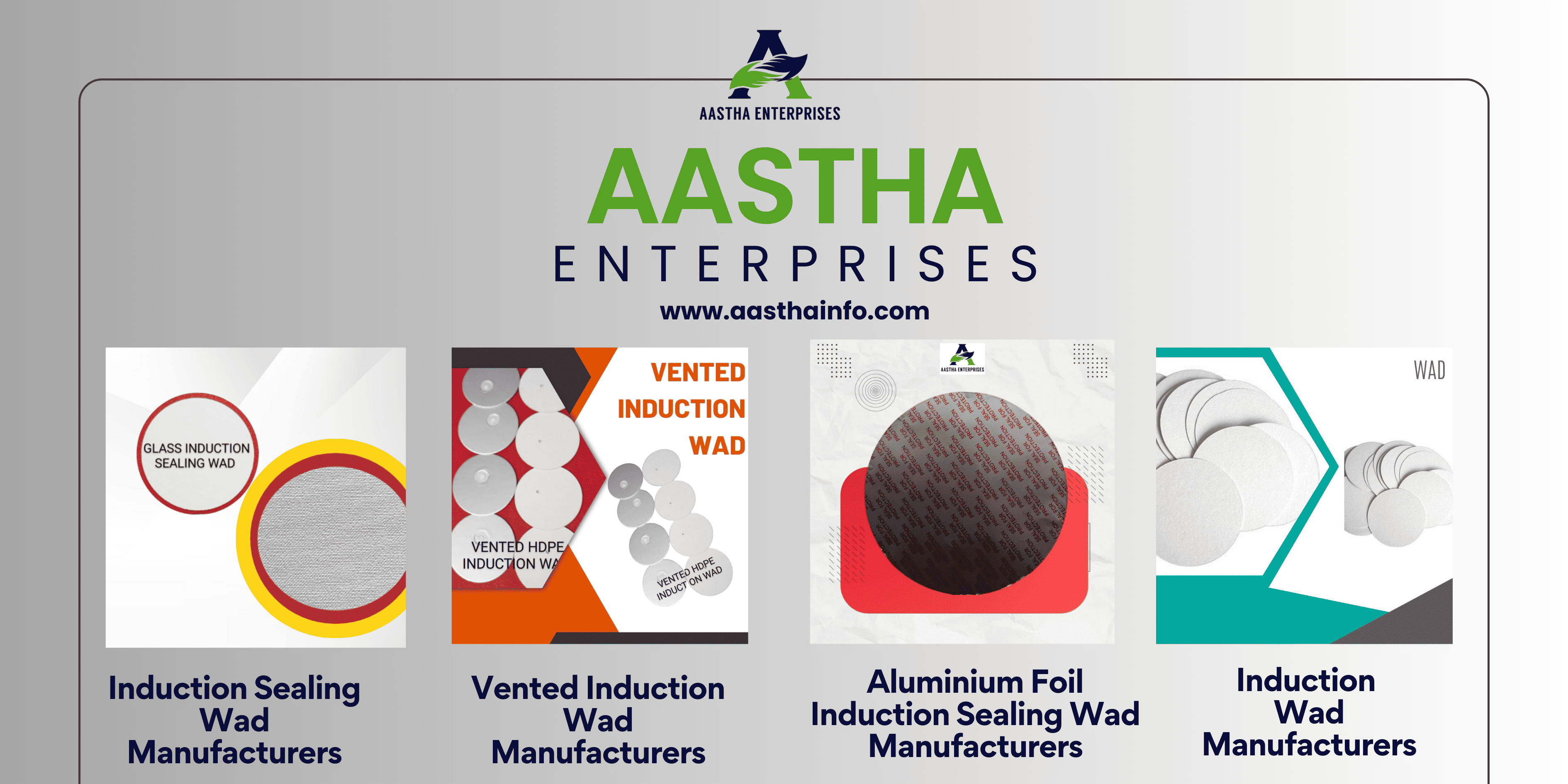

Leading manufacturers of high-quality induction sealing wads in India for secure and reliable packaging.

Leading manufacturers of high-quality induction sealing wads in India for secure and reliable packaging.

When it comes to product safety, leak prevention, and extending shelf life, induction sealing wads play an indispensable role. Whether you’re in the pharmaceutical, food & beverage, cosmetic, or chemical industry, choosing the right Induction Sealing Wad Manufacturers can make all the difference in your packaging process.

In India, the demand for premium sealing solutions is growing at an exponential level, and a few manufacturers have emerged as the torchbearers of this industry. If you want the best Induction Sealing Wad Manufacturers, this guide is here to assist you in identifying the industry best.

Induction wads are most responsible for creating a hermetic seal to the mouth of a container. Leakage and contamination are not only avoided, but also the end-user is assured of product authenticity and safety.

Starting from sealing powders, liquids, or semi-solids, induction wads are increasing product shelf life, providing tamper evidence, and boosting customer confidence.

India has the world's best technologically advanced and innovative Induction Sealing Wad Manufacturers. They adopt precision technology alongside good quality raw materials to make wads of different containers such as plastic, glass, and metal.

Glass bottles are extensively applied in pharma and food processing industries because of their non-reactive nature. Special solutions, though, are needed for effective sealing. Top Glass Induction Sealing Wad Manufacturers in India are developing heat-induction seals with higher adhesion and strength without glass breakage.

The wads are temperature induction machine compatible and possess enhanced barrier properties, which lead to no contamination and retention of freshness.

For high-quality sealing solutions, Aluminium Foil Induction Sealing Wad Manufacturers in India provide some of the most trustworthy ones. Aluminium foil wads are used because they have very good barrier properties and are compatible with different material containers.

The wads are also resistant to moisture, oxygen, and UV light and therefore suitable for sensitive products such as food, medicine, and cosmetics.

Each packaging need is not the same. Thus, a good Induction Wad Manufacturer offers customization according to your specific application needs. Whether wad diameter, material composition, or print on sealing surface, Indian manufacturers can offer customized solutions.

Customization also encompasses wads for metal, glass, PET, HDPE, and LDPE packaging, which find wide application in lubricant, agrochemical, and personal care applications. Others specialize as Vented Induction Wad Manufacturers, who offer breathable wads to compensate for pressure in specific applications.

Well-established Induction Sealing Wad suppliers invest a lot of resources into R&D as well as quality check. They adhere to extremely high industry standards and go through a multitude of quality checks to guarantee that every wad is in top condition to perform perfectly in actual use conditions.

They test all the wads, including leak testing, adhesion testing to peel strength analysis, through a performance test of ultimate. These practices distinguish the best Induction Wad Manufacturers in the country.

Not the sealing wads themselves alone. Indian packaging sector is also backed up by skilled Container Mould Manufacturers who create and manufacture precision moulds for plastic containers as well as glass containers. Coordination with mould and wad manufacturer ensures sealing procedure to be smooth, efficient, and completely synchronized with your packing lines.

A few of the parameters to be remembered while choosing a sealing wad company in India are as follows:

Expertise and Experience: The longer years of business, the better process and quality product.

Material Quality: Make sure they use FDA-approved and food-grade material wherever required.

Customization Option: See if they have custom wads for your particular application.

Delivery and Service: Timely delivery and technical servicing can prevent your line of production from expensive shutdowns.

India has emerged as a trend-setting country of high-quality induction sealing solutions at a whirlwind pace. Perhaps you are seeking Glass Induction Sealing Wad Manufacturers, Aluminium Foil Induction Sealing Wad Manufacturers, or acoustic Induction Wad Manufacturer choices. India has plenty to provide you with. Indian manufacturers, spurred by advances in design, material, and functionality, are helping companies across the globe seal their products with confidence.

For inquiries, detailed product information, or to discuss your specific requirements, feel free to reach out to our dedicated team.

Plot no 37, sector 10A, Vasundhara, Ghaziabad, Uttar Pradesh, India -201012

Plot no 37, sector 10A, Vasundhara, Ghaziabad, Uttar Pradesh, India -201012